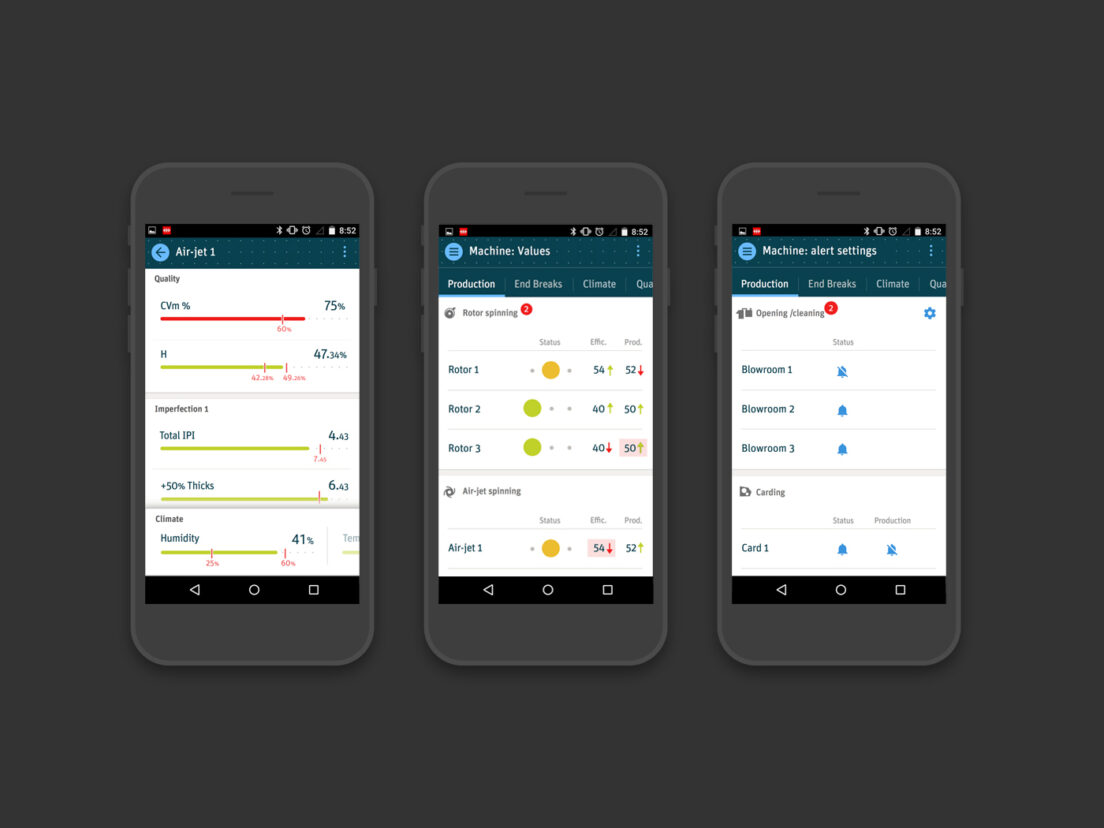

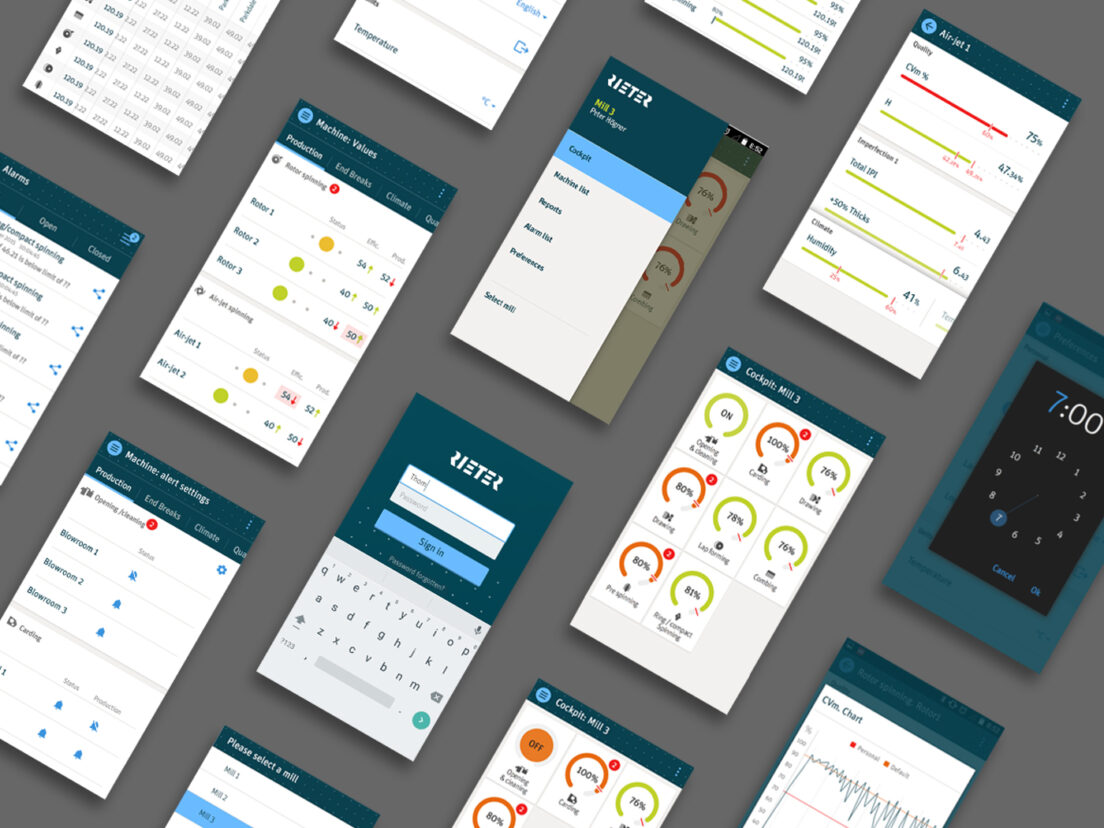

With the Essential app, the Winterthur spinning machine manufacturer Rieter provides its customers with a central element of the “Digital Spinning Suite”. The app uses data from sensors from the entire spinning process. The cockpit module displays key figures for production, quality and energy in real time and presents the information clearly. This means that production can be continuously monitored and optimized. In the alert module, a clever alert mechanism reports errors before they become problems. This allows operators to react quickly and reduce expensive production downtimes to a minimum.

The app acts as a digital service layer around the Rieter machine park. It ensures qualified decisions, shows opportunities for improvement and ensures economically successful operations.

User-Centered Design Ensures Efficient Use

NOSE's Interactive Experience team supported the development of the mobile application with a process based on personas and scenarios. To do this, we simulated the different roles in production. We played through different, typical operating procedures and known crisis situations in interactive prototypes. On this basis, we were able to optimize the use of the app and embed it in efficient communication. The extensive real-time information required for this was presented in a format that can be quickly interpreted.

NOSE's Interactive Experience team supported the development of the mobile application with a process based on personas and scenarios. To do this, we simulated the different roles in production. We played through different, typical operating procedures and known crisis situations in interactive prototypes. On this basis, we were able to optimize the use of the app and embed it in efficient communication. The extensive real-time information required for this was presented in a format that can be quickly interpreted.